Flexible permanent magnets

TROMAFLEX® – the name of the flexible permanent magnet developed by Max Baermann – consists of a mixture of a highly coercive magnetic powder (barium ferrite or strontium ferrite) and a high-quality flexible plastic. This mixture has a magnetic material content of up to 90% by weight. It is granulated into small particles and

a.) Rolled out into thin films or sheets in calenders (calendered) or

b.) Injected into strips or profiles in continuous lengths in extruders (extruded)

The foils, strips or profiles obtained in this way are then magnetised in a downstream process.

TROMAFLEX®flexible permanent magnets are the preferred choice wherever the use of conventional rigid magnets is impractical, too expensive or even impossible. TROMAFLEX®conforms to curved surfaces, can be punched and cut with scissors, and can be bonded to wood, plastics, metal, etc.

Thanks to the ease with which TROMAFLEX®are formable, extruded magnetic profiles can be provided with projections, grooves, dovetails, curves, and the like for the purpose of assembly assistance at low mould costs, thus shortening assembly times and saving costs. Today, flexible permanent magnets – sometimes also called magnetic rubber – have established themselves firmly in technology.

Based on the invention of Max Baermann in 1956, the world production of flexible magnetic materials is now estimated at several 100 tons per month.

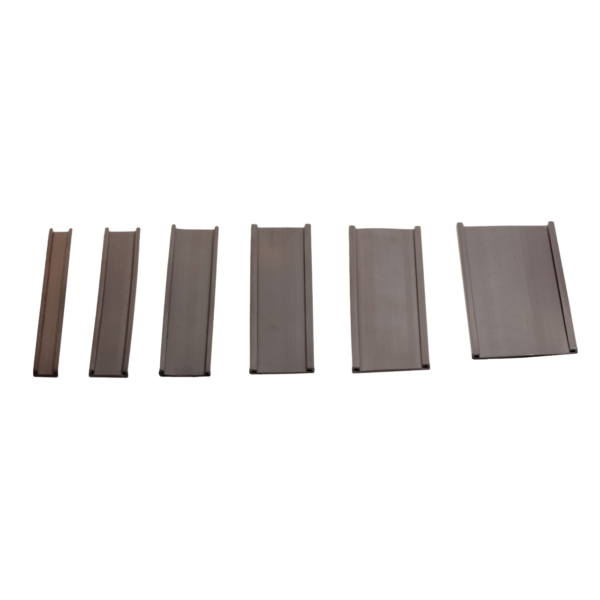

Magnet profiles

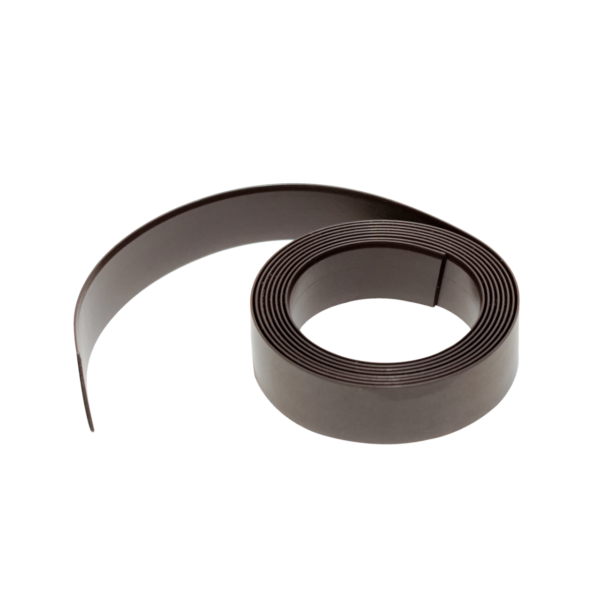

Magnet strips