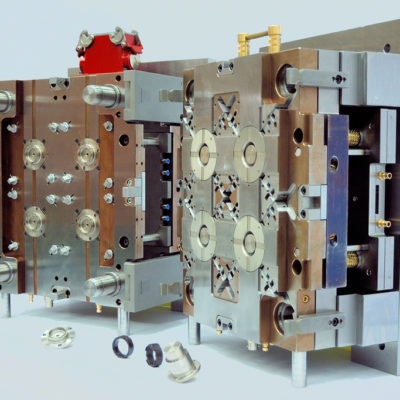

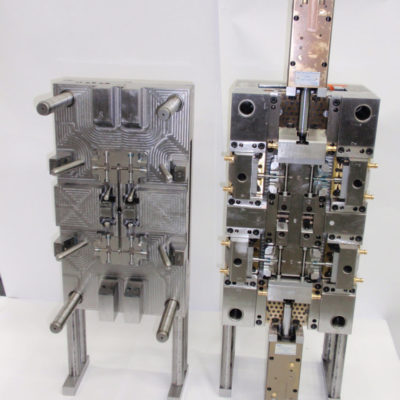

Mould development

The basis for the production of plastic-bonded permanent magnets:

The design and manufacture of our moulds is aimed at meeting the high demands of our customers in terms of function and product quality throughout the entire product life.

Our work therefore begins with the mould and application-oriented consultation during the development and design of a new article.

The customer-specific requirements for new magnets are implemented constructively by experienced design engineers in close cooperation with the R&D and moulding departments using modern CAD systems and in-house standards.

By using CAM systems and the latest manufacturing technology, we produce high-quality and high-precision individual components as well as integral injection moulds.

Qualified and experienced specialist toolmaking personnel, who are familiar with the requirements of our customers’ industries as a result of their many years of service with the company, guarantee the precise implementation of the tools, a problem-free start to series production and the cost-effective maintenance and servicing of the series tools.