Magnetisation – Magnetic characteristics

Magnetic characteristics of TROMAFLEX® – Grades

(average values from different production batches)

| TROMAFLEX® | 324 | 325 | 928 |

| hard ferrite | 3/24 p | 3/25 p | 9/28 p |

| Br (mT) | 127 | 142 | 220 |

| BHC(kA/m) | 91 | 98 | 170 |

| IHC(kA/m) | 240 | 250 | 280 |

| (BH) max. (kJ/m³) | 3.0 | 3.5 | 9.0 |

| Filling degree (g/cm³) | 3.4 | 3.73 | 3.5 |

Types of magnetisation

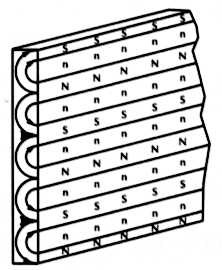

One-sided multipole magnetised

n = neutral zone

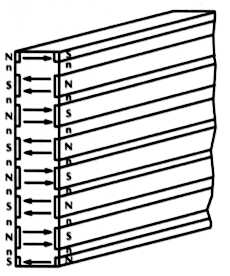

Two-sided multipole magnetised

n = neutral zone

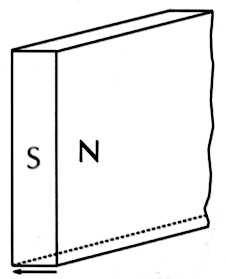

Axially magnetised

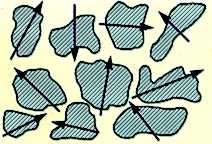

Method of manufacturing anisotropic flexible magnets

TROMAFLEX® 928

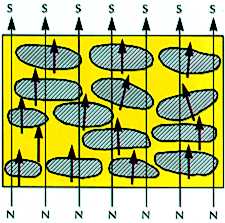

Using special oxide ceramic permanent magnet materials, an increase in the magnetic energy density of plastic-bonded permanent magnets can be achieved by suitable manufacturing processes. This results in a significant increase of the adhesive force compared to isotropic permanent magnets.

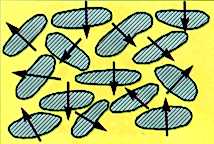

In the production of anisotropic permanent magnets, the strontium ferrite particles, which are usually disk-shaped, are mechanically aligned in the heated plastics surrounding them in such a way that as large a proportion as possible of their preferred magnetic axes are aligned parallel in the required direction.

Barium ferrite isotropic

TX 324/325

Strontium ferrite anisotropic

TX 928

Aligned preferred axis